Jet Air Heaters

Temperatures up to 1400ºF / 760ºC

3kW - 8kW

Built-in Over-temp Protection Capability

Built-in Type K thermocouples

Compact footprint

Ideal for compressed air or regenerative blower

Applications: aerospace, automotive, electronics, plastics, medical, food & beverage, printing, OEM systems

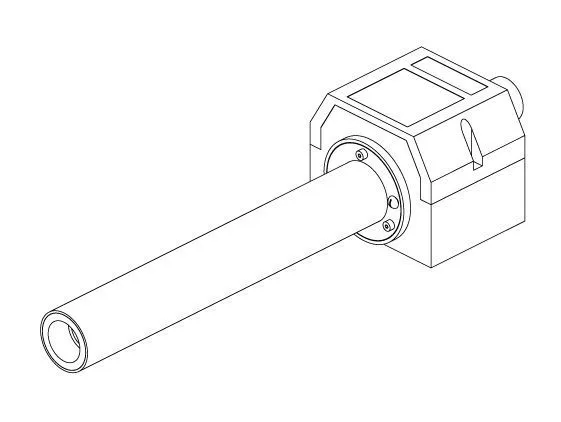

A compact electric inline heating solutions for air and inert gases

The TUTCO SureHeat Jet is a compact, high-performance process air heater engineered for applications that demand precise temperature control, rapid heat-up, and reliable operation in a small footprint. Designed for use with compressed air or regenerative blowers, the Jet is capable of delivering air temperatures up to 1400 °F (760 °C), making it an ideal solution for industries that require concentrated, high-velocity heat in limited space.

Unlike conventional inline heaters, the Jet incorporates dual Type K thermocouples (inlet and outlet) and integrated flow loss protection to provide superior safety and accuracy. With power ratings of 3kW and 8kW at 240V single-phase, the Jet balances power and efficiency, ensuring consistent results while minimizing risk of element failure.

The Jet is part of TUTCO SureHeat’s Closed-Loop Process Heater line, engineered to work seamlessly with our dedicated control panels. This pairing enables precise voltage regulation, overshoot protection, and stable performance under varying airflow conditions. Rugged stainless-steel construction and simplified wiring via a terminal block make the Jet easy to install and reliable in continuous industrial use.

From automotive bonding and plastic forming to drying, curing, packaging, and thermal testing, the Jet excels in any process where high heat and compact size are critical. Trusted by OEMs and manufacturers worldwide, it delivers the performance and safety needed to optimize throughput, improve quality, and extend equipment life.

Discover which Jet heater is ideal for your application

Use the table below to determine the optimal Jet heater for your application, or contact TUTCO SureHeat to discuss specific process requirements and receive expert support.

Features & Benefits

- High-Temperature Capability – Reliable heating up to 1400 °F (760 °C).

- Compact, High-Performance Design – Small footprint for tight spaces without sacrificing power.

- Dual Type K Thermocouples – Two sensors (inlet and outlet) enable precise temperature monitoring and ensure safety.

- Built-in Flow Loss Protection – Safeguards heater integrity and prolongs service life.

- Simple Wiring & Mounting – Terminal block simplifies installation; includes ground stud and mounting provisions

- Closed-Loop Compatible – Seamlessly integrates with TUTCO SureHeat Control Panels for precise voltage control and safeguard measures.

- Regulatory Certified – UL Recognized, CE, and RoHS compliant.

Specifications

- Air Temperature: Up to 1400 °F (760 °C)

- Power Options: 3kW (12.5 A) or 8kW (33.3 A) at 240 V (1 Ø)

- Minimum Airflow: 2 SCFM for accurate control

- Airflow at Max Temp: 6–15 SCFM

- Maximum Pressure: 60 psi

- Maximum Inlet Temperature: 200°F (93°C)

- Thermocouples: Two built-in Type K sensors (inlet & exit)

- Certifications: UL Recognized, CE, RoHS

Industries & Applications

Ideal for high-velocity heat applications in constrained installations, the TUTCO SureHeat Jet delivers precise, reliable performance across a variety of industries:

- Automotive – Efficiently supports processes such as bonding body panels, curing adhesives, vacuum forming, and component testing or thermal simulation, ensuring consistent heat in tight production areas.

- Plastics – Optimized for salt removal, forming, bending, bonding, and heat staking, providing fast ramp-up and uniform temperature for quality results.

- Electronics & Semiconductor – Delivers controlled, high-velocity air for quick drying, component sealing, soldering, or curing delicate assemblies without damaging sensitive materials.

- Medical & Pharmaceutical – Ideal for sterilization, precision drying, packaging, and laboratory testing, helping facilities maintain regulatory standards while reducing process time.

- Printing & Converting – Supports shrink wrapping, laminating, coating, and drying processes, maintaining consistent temperatures for uniform finishes and high-quality output.

- General Industrial & OEM Applications – Perfect for air knives, small-scale curing, drying tunnels, and custom machinery, offering flexible integration for manufacturers with constrained spaces or specialized process requirements.

A Line of Industrial Control Solutions from the Heating Experts

TUTCO’s depth of expertise uniquely qualifies us to manufacture control panels for the heaters we produce, as reflected in our unwavering commitment to quality. Our engineers have leveraged the latest technology in heater controls and safety features to create a line of totally customizable controllers well-suited for industrial facilities and OEMs. Our controllers utilize power controllers, temperature controllers, and thermocouples to continuously monitor and maintain consistent output voltages to the heater.

Regardless of fluctuations in the process or changes in airflow, the temperature is continually monitored to meet process requirements and safeguard the heater. Each controller features LAN connectivity via an RJ45 port, which allows the controller to communicate and retrieve data from a remote HMI or another external device, such as a data logger or webpage.

Closed-Loop (Feedback) Control

Closed-loop heater control systems use a power controller, temperature controller, and thermocouple to monitor and maintain a constant output temperature, regardless of changes in airflow. The typical temperature controller provides a convenient display of the air temperature (not the element temperature).

Temperature Controller

- Use only digital temperature controllers with Type K thermocouple inputs.

- The temperature control output must match the input of the power controller (e.g., 4–20 mA or 0–10 VDC).

- A standard PID-type control with a wide proportional band works best to minimize temperature overshoot.

- PID parameters may be auto-tuned, but only at temperatures below the maximum rating of the heater. Monitor the heater temperature rise and turn power off immediately if it exceeds the heater’s specification during the auto-tune cycle.

Power Controller

SCR (Silicon Controlled Rectifier) power controllers provide the smoothest power regulation for electric air heaters. Power controllers, such as SSR (Solid State Relays) or other fast-switching controllers are also used with our heaters. Contact TUTCO SureHeat for details.

Resources

Why choose TUTCO SureHeat?

Industry Expertise: With decades of experience in industrial heating solutions, TUTCO SureHeat is a trusted name in the industry.

Reliable Performance: Our heaters are designed for consistent, repeatable results, ensuring quality and efficiency in your processes.

Comprehensive Support: We offer technical support, custom solutions, and integration assistance to meet your specific needs.

Global Reach: Our products are used worldwide, providing proven solutions in various industries.

The TUTCO SureHeat Jet stands out in the market as a compact yet powerful heating solution that combines precision, reliability, and safety in one streamlined design. Where other inline heaters may compromise on control or durability, the Jet delivers consistent high-temperature performance with built-in safeguards, ensuring long service life and reduced downtime. Backed by TUTCO SureHeat’s proven engineering and global support, the Jet is the clear choice for manufacturers who need dependable heat in tight spaces without sacrificing efficiency or quality.

Frequently Asked Questions

The Jet is ideal for applications in automotive, plastics, electronics, medical, packaging, and general manufacturing where compact, high-velocity heat is essential for processes such as drying, curing, bonding, or forming.

The Jet pairs seamlessly with TUTCO SureHeat’s closed-loop control panels, providing precise voltage regulation, overshoot protection, and stable performance under varying airflow and temperature conditions.

Yes. The Jet is designed for use with either compressed air or regenerative blowers, making it suitable for a wide range of industrial setups that require clean, high-velocity air.

The Jet stands out for its compact size, high-temperature capability, and dual Type K thermocouples that provide precise inlet and outlet temperature monitoring. It also features built-in flow loss protection for added safety and reliability.