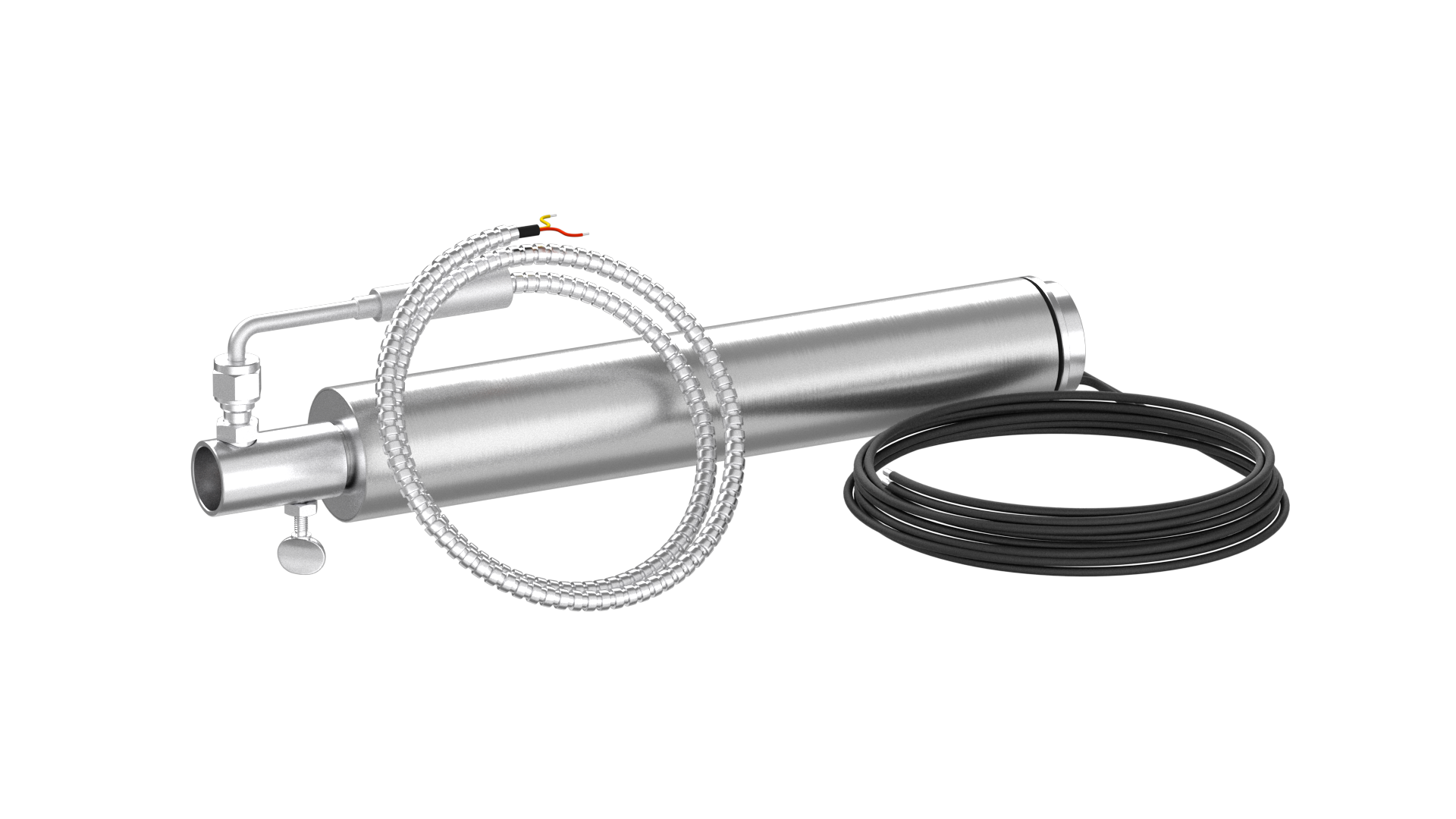

Serpentine II Heaters

Max temperature up to 1500ºF / 815ºC

Modular and Durable Design – Stainless steel construction with field-replaceable Serpentine coil for easy maintenance and long service life

Energy Efficient and Safe – Triple-pass design minimizes heat loss, reduces energy consumption, and maintains a cooler outer shell for operator safety

CE RoHS

Applications: Ideal for automotive, aerospace, plastics, electronics, food processing, medical, printing, and general industrial OEM systems

High-Performance Modular Air Heating Solution for OEM Applications

The TUTCO SureHeat Serpentine II Triple Pass Heater is engineered to deliver precise, reliable, and high-efficiency air heating in the most demanding industrial environments. Capable of reaching exhaust temperatures up to 1,500°F (815°C) and rated for inlet pressures up to 25 psi / 1.7 bar, this heater provides steady, high-temperature airflow for processes where accuracy, repeatability, and performance are critical. Its innovative triple-pass design maximizes heat transfer efficiency, resulting in faster ramp-up times, uniform temperature distribution, and reduced energy waste.

Built with rugged stainless steel construction, the Serpentine II is designed for durability and long-term reliability under continuous industrial use. Its compact and modular form factor makes it easy to install, maintain, and integrate into both OEM machinery and standalone systems. Whether used for drying, curing, sealing, or other high-precision heating applications, the Serpentine II offers unmatched versatility and consistent performance across a wide range of industries, including automotive, aerospace, electronics, and general manufacturing.

Discover which Serpentine II heater is ideal for your application

Use the table below to determine the optimal Serpentine II heater for your application, or contact TUTCO SureHeat to discuss specific process requirements and receive expert support.

Product List

| F029765 Length "A" | 8.20" (208mm) |

| F029766 Length "A" | 8.20" (208mm) |

| F029767 Length "A" | 8.20" (208mm) |

| F060418 Length "A" | 8.63" (219mm) |

| Serpentine II Diameter "B" | 0.63" (16mm) |

| Serpentine II Housing "C" | 10.0" (254mm) |

| Serpentine II Housing "D" | 9.0" (229mm) |

| Serpentine II Housing Diameter "E" | 1.6" (40mm) |

| Serpentine II Housing Diameter "F" | 0.7" (18mm) |

| Serpentine II Housing Inlet Diameter "G" | 3/8" NPT |

Features & Benefits

- High-Temperature Capability – Reaches exhaust temperatures up to 1,500°F (815°C), supporting demanding industrial processes.

- High-Pressure Tolerance – Rated for 150 PSI maximum inlet pressure, suitable for compressed air systems.

- Triple-Pass Modular Design – Field-replaceable Serpentine coil housed in a triple-pass stainless steel housing for efficient heat transfer and easy maintenance.

- Safe and Efficient Operation – Outer shell remains cooler thanks to triple-pass airflow design, reducing radiant heat loss and providing safe operation.

- Compact & Flexible Integration – Easily fits into OEM systems, production lines, or standalone setups without sacrificing performance.

- Durable Construction – Made from 304 stainless steel, resistant to corrosion and built for long-term industrial use.

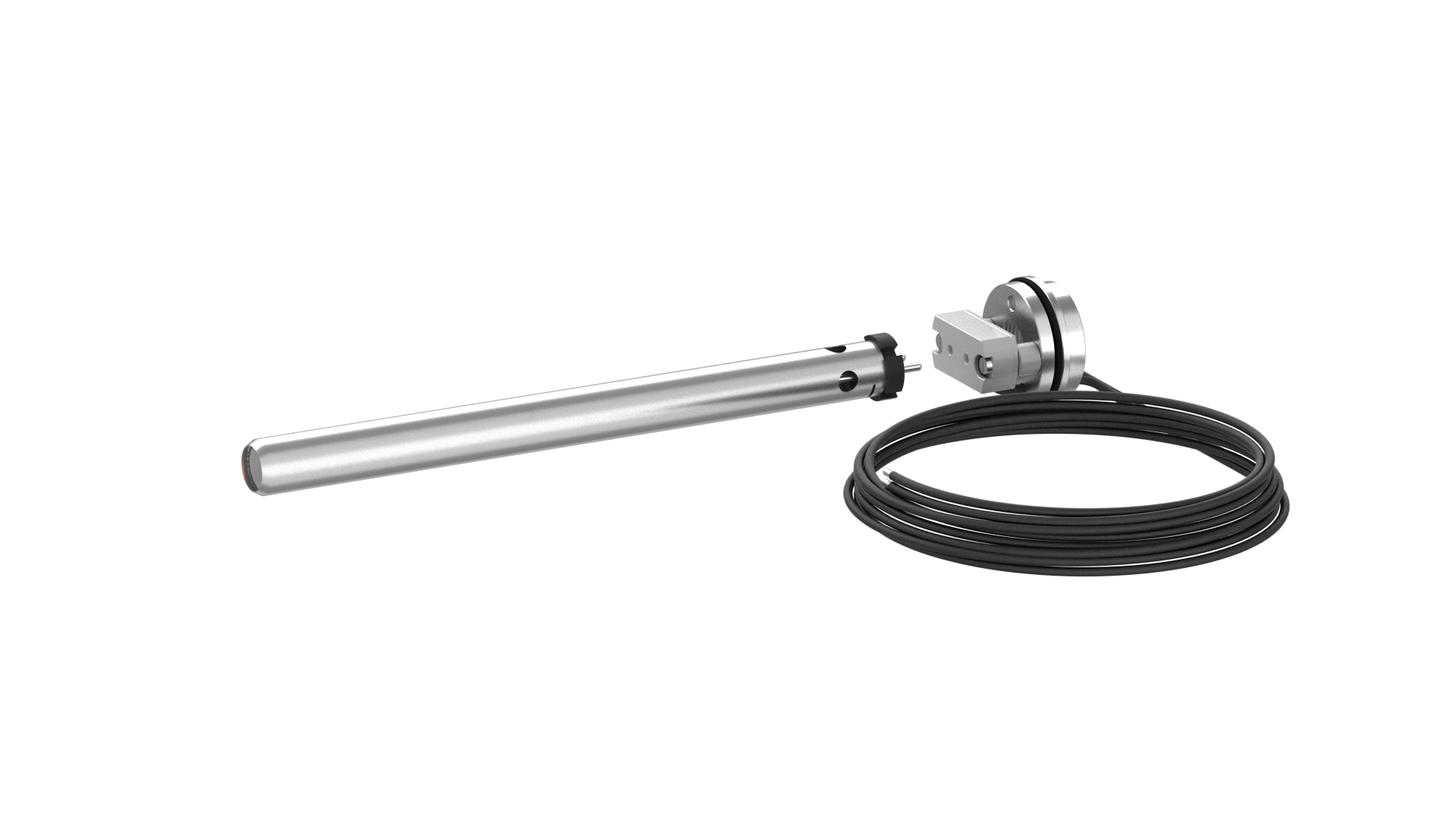

- Controller Compatibility – Works with digital temperature controllers using Type K thermocouples for precise, closed-loop temperature control.

Specifications

- Maximum Exhaust: Temperature Up to 1,500°F (815°C) - (2-stage model)

- Maximum Inlet Pressure: 25 psi / 1.7 bar

- Inner Tube Diameter: 0.63" (16 mm)

- Outer Housing Diameter: 1.6" (40 mm)

- Housing Material: 304 Stainless Steel

- Mounting Style: Clamp

- Power Options: 2kW to 3.6kW

- Voltage Options: 240V

- Control Compatibility: Digital temperature controllers with Type K thermocouples

Real World Results

- Improved Process Efficiency – Rapid and precise heat-up reduces cycle times, allowing manufacturers to increase throughput and improve overall productivity without sacrificing quality.

- Consistent Product Quality – The triple-pass design provides uniform heating across the air stream, minimizing defects in curing, drying, forming, and sealing processes. This precision helps ensure every product meets exacting standards.

- Energy Savings – Efficient heat transfer and reduced radiant heat loss in the triple-pass design lower energy consumption, helping facilities reduce operational costs and meet sustainability goals.

- Durable & Low Maintenance – Constructed from 304 stainless steel with a replaceable Serpentine coil, the heater is built for long-term reliability while reducing downtime and maintenance costs.

- Enhanced Safety – The triple-pass airflow cools the outer shell, reducing radiant heat exposure, while controlled airflow and precise temperature monitoring protect operators and surrounding equipment.

- Flexible Application – Suitable for OEM machinery, production lines, or standalone systems, the Serpentine II provides high-temperature, high-precision heating for a wide range of industries, including automotive, aerospace, plastics, electronics, food processing, medical, and more.

Notes

- Always ensure air is flowing before powering the heating element

- Regulate the ramp up time using the potentiometer to control the AC voltage

- Requires a temperature controller with 100ms cycle time

- Temperatures are measured by 3/16” “K” T/C sensor Part #F039272 mounted inside TC holder #F029485

- TC Holder mounted on exit of #F029763 Housing Assembly

- Use of other sensor types and mounting locations can result in heater damage

- Minimum airflow for accurate control is 60 SCFH Maximum air temperature is 1500°F (815°C) *3.6kW, 2-Stage F060418

- Operating above this curve voids the product warranty

Applications

- Automotive & Transportation – Adhesive activation, panel bonding, welding, heat forming, component testing, and simulation. Ensures strong, durable bonds and consistent heat for quality manufacturing processes.

- Aerospace & Defense – Composite curing, thermal simulations, component testing, and de-icing systems. Provides reliable, precise heating for critical aerospace applications.

- Plastic Processing & Packaging – Plastic welding, shrink fitting, forming, bending, sealing, and heat shrinking. Supports high-quality, repeatable results in manufacturing and packaging.

- Electronics & Semiconductor – Solder reflow, wafer processing, quick drying, component sealing, and curing adhesives. Maintains uniform heat for sensitive, high-precision processes.

- Food & Beverage – Drying, sterilization, baking, coating, and shrink-wrapping. Enhances production efficiency while ensuring consistent product quality.

- Medical & Pharmaceutical – Sterilization, packaging, laboratory testing, and other precision heating applications. Supports strict hygiene and process requirements.

- Printing & Converting – Ink drying, laminating, coating, embossing, and shrink wrapping. Improves process speed and consistency across production lines.

- General Industrial & OEM Machinery – Hot air knives, drying tunnels, small-scale curing, and integration into custom OEM systems. Provides versatile solutions for diverse industrial processes.

Resources

Why choose TUTCO SureHeat

Industry Expertise: With decades of experience in industrial heating solutions, TUTCO SureHeat is a trusted name in the industry.

Reliable Performance: Our heaters are designed for consistent, repeatable results, ensuring quality and efficiency in your processes.

Comprehensive Support: We offer technical support, custom solutions, and integration assistance to meet your specific needs.

Global Reach: Our products are used worldwide, providing proven solutions in various industries.

The TUTCO SureHeat Serpentine II Heater stands out in the market for its rapid, precise, and repeatable heating. It delivers improved product quality, higher throughput, and greater energy efficiency in every application.Whether you're integrating it into OEM equipment or using it in standalone applications, this heater offers the performance and versatility needed to meet your heating requirements.

Frequently Asked Questions

Efficiency: Triple-pass airflow reduces radiant heat loss and energy consumption.

Safety: Outer shell remains cooler, protecting operators and surrounding equipment.

Durability & Maintenance: Constructed from 304 stainless steel with a replaceable Serpentine coil for long-term reliability and easy service.

Compact & Flexible: Its modular design fits OEM machinery, production lines, or standalone systems without sacrificing performance.

The heater is used across a wide range of industries, including automotive, aerospace, electronics, plastics, food processing, medical, and general manufacturing. Typical applications include adhesive activation, composite curing, solder reflow, heat shrinking, drying, and sterilization, providing precise, repeatable heating for critical processes.

The innovative triple-pass design maximizes heat transfer efficiency by passing air through the heating element three times. This results in faster ramp-up times, uniform temperature distribution, reduced energy waste, and a cooler outer shell for safer operation. It also allows for field-replaceable Serpentine coils, simplifying maintenance.

The Serpentine II can reach exhaust temperatures up to 1,500°F (815°C) and is rated for inlet pressures up to 25 PSI / 1.7 bar. This makes it ideal for high-precision industrial processes requiring steady, high-temperature airflow, such as drying, curing, sealing, and forming.