TUTCO SureHeat Partners with RIFT to Advance Iron Fuel Technology™

As the world shifts toward a low-carbon future, hydrogen has the potential to become one of the most useful forms of energy carrier due to its low carbon emission properties. However, the efficient transportation of hydrogen on a large scale still presents significant challenges. Hydrogen is a highly volatile and light gas with rather low energy density, making its storage and shipping complex and costly. Typical methods of transporting hydrogen involve converting the hydrogen into ammonia or transforming it into a liquid under extremely low temperatures and high pressures.

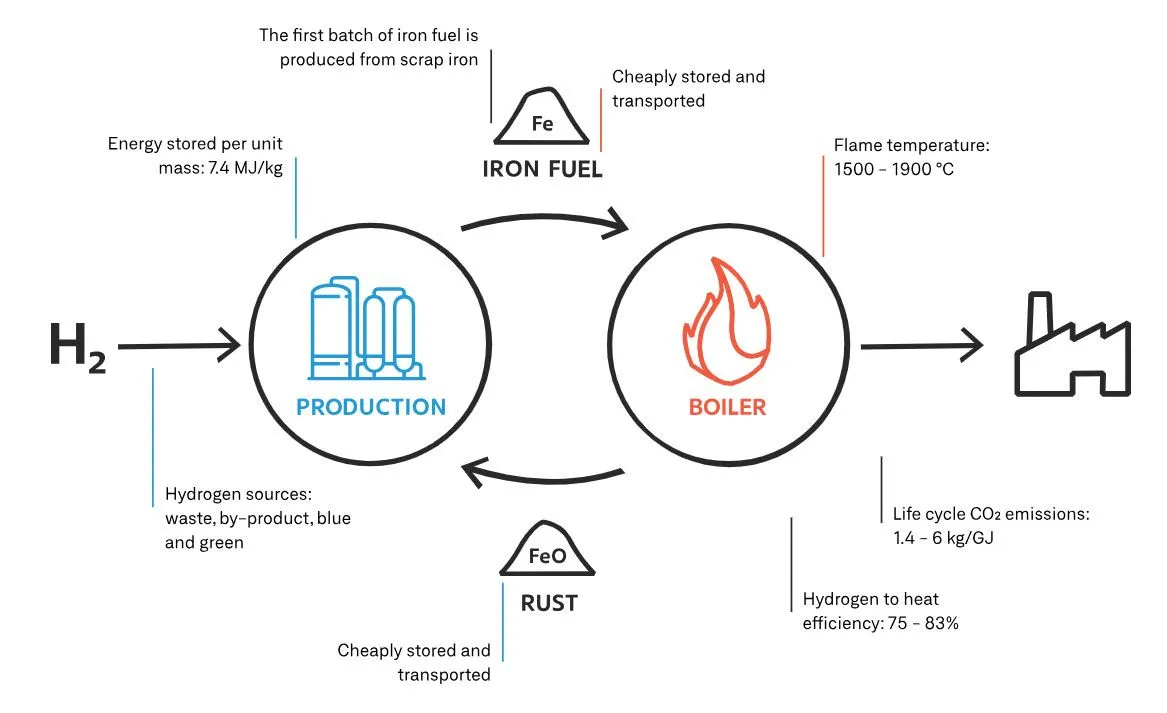

An innovative method attracting a lot of attention is Direct Reduction of iron oxide (rust). In this process, hydrogen reduces iron oxide to elemental iron powder. The only byproduct of this process is pure water. The elemental iron can then be combusted, yielding a high-temperature solid fuel, which when combusted oxidizes into rust. Following this, the rust can be collected, shipped, and reduced again using hydrogen—a clean, reusable cycle.

Once energy is transported as a solid it becomes easy to facilitate the movement of renewable energy produced in offshore wind farms or in sunny Sahara to other areas where it is in high demand. This method highlights the potential of this technology. At the forefront of this innovation is RIFT, a company located in Netherlands with the ambitious goal of cutting 1 gigaton CO₂ emissions annually by 2050. Their Iron Fuel Technology™ harnesses the power of iron powder as a circular, carbon-free fuel, giving industries a viable way to transition away from fossil fuels without sacrificing performance.

Iron Fuel Technology™ operates like a rechargeable battery for heat generation. Visualize iron powder as a unique energy carrier, akin to a charged battery. Through controlled combustion, this iron fuel transforms into high-temperature energy, serving diverse needs across industries. In the combustion phase, iron fuel efficiently burns in a specialized boiler, producing hot water, steam, or hot air. Remarkably, this process avoids direct CO₂ emissions and maintains ultra-low NOx emissions. Post-combustion, the production process converts rust (iron oxide) back into iron fuel using a hydrogen source. This flexibility completes the sustainable cycle, offering continuous and environmentally friendly energy solutions.

To bring this vision to life, RIFT has partnered with TUTCO SureHeat to develop a key component of the process: a high-performance heating solution for the DRI system. In this setup, hydrogen must be heated to elevated temperatures under moderate pressure in order to effectively reduce iron oxide into pure iron powder. To keep operational costs low, the system needs to reach target temperatures quickly and efficiently.

TUTCO SureHeat's Specialty Flanged Inline (SFI) Heaters were designed specifically for this purpose. These heaters deliver:

- Reliable High-Temperature Performance – Engineered to handle the demanding conditions required for hydrogen heating in the DRI process.

- Compact, Space-Saving Design – Ideal for integration into RIFT’s system layout without taking up unnecessary room.

- Fast Heat-Up Times – Boosts process efficiency and reduces energy consumption.

- Flexible, Scalable Configuration – Adaptable to various facility sizes and production needs.

Iron Fuel Technology™ is more than a concept—it’s a practical, scalable solution for multiple industries, including:

- Manufacturing & Heavy Industry – Carbon-free heat for sectors like chemicals, petrochemicals, and metal production.

- Food & Beverage – A sustainable alternative for steam generation and other heat-intensive processes.

- District Heating – Clean hot water for residential and industrial heating systems.

- Energy Grid Support – A stable, storable energy source to balance supply and demand alongside solar and wind.

Together, TUTCO SureHeat and RIFT are demonstrating that clean energy technologies don’t have to compromise on performance or practicality. As industries push toward decarbonization, partnerships like this are helping pave the way to a cleaner, more sustainable future. We’re proud to be part of this groundbreaking work.

While Iron Fuel Technology™ is indeed a practical and scalable solution across multiple industries, RIFT is currently working towards first-time commercialization. Their initial focus is on the Food & Beverage, Specialty Chemicals, and Pulp & Paper sectors, where they are actively developing their first commercial projects. Other industries such as steel, metal production, and energy grid support align well with the broader potential of the technology, but they are not RIFT's immediate focus. Unlike current demonstration pilots, these upcoming projects will mark the first real-world commercial applications of the technology.