Hot Air Tools

Temperatures up to 1400ºF / 760ºC

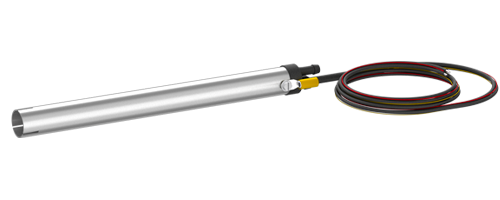

Durable stainless-steel body, compact for tight installations

Control & Safety: Built-in Type K thermocouples, closed-loop operation, over-temperature protection

Power Options: 1.5 kW – 3.58 kW, 120V and 240 V single-phase

Made in the USA

Applications: automotive, transportation, plastics, packaging, electronics, medical, pharmaceutical, and OEM systems

A compact, high-performance closed-loop spot air heater

The TUTCO SureHeat Hot Air Tool is a compact, high-performance industrial air heater engineered for precision spot heating, localized process heating, and OEM applications where accuracy, speed, and reliability are critical. Capable of reaching outlet temperatures up to 1400 °F (760 °C) with high-velocity, focused airflow, the Hot Air Tool delivers fast, uniform heat even in tight or hard-to-reach spaces, making it ideal for applications where conventional hot air blowers, heat guns, or spot heaters are insufficient.

Constructed from rugged stainless steel and equipped with integrated Type K thermocouples, the Hot Air Tool ensures precise temperature monitoring and closed-loop control, maintaining consistent output even under variable airflow conditions. Its compact, lightweight design allows for easy integration into OEM systems, production lines, or manual process setups, without sacrificing durability or safety.

The Hot Air Tool is versatile across a wide range of industries, including automotive, plastics, electronics, medical, printing, and general manufacturing, supporting processes such as adhesive activation, shrink wrapping, component sealing, curing, forming, and small-scale drying.

Compared to competitor products, the TUTCO SureHeat Hot Air Tool stands out with its combination of robust temperature capability, precision control, high-velocity airflow, and long-term reliability, delivering repeatable, high-quality results in demanding industrial environments. Backed by TUTCO’s decades of experience in industrial heating solutions, it is a trusted choice for manufacturers seeking efficient, safe, and consistent localized heating.

Discover which Hot Air Tool is ideal for your application

Use the table below to determine the optimal Hot Air Tool for your application, or contact TUTCO SureHeat to discuss specific process requirements and receive expert support.

Features & Benefits

- High-Temperature Capability – Reaches up to 1400 °F (760 °C) for demanding spot-heating applications.

- Precision Closed-Loop Control – Built-in thermocouple and compatibility with TUTCO SureHeat Control Panels for stable, repeatable heating.

- Compact, Durable Design – Stainless steel body engineered for tight installations and long-term reliability.

- Fast Ramp-Up – Delivers quick, high-velocity heat for improved process efficiency.

- Flexible Integration – Mounts easily into OEM systems, production lines, or standalone applications.

- Enhanced Safety – Over-temperature protection ensures safe operation in continuous industrial environments.

- Energy Efficient – Optimized for minimal energy waste, maintaining only the required temperature for your process.

Specifications

- Maximum Air Temperature: Up to 1400 °F (760 °C)

- Power Source: 120V/240V

- Temperature Control Cycle Time: 100ms Minimum

- Thermocouples: Built-in Type K

- Airflow: High-velocity for focused spot heating

- Maximum Air Pressure: 60 psi

- Construction: Stainless steel, compact design

- Control: Compatible with TUTCO SureHeat Control Panels; closed-loop monitoring

- Mounting Options: Inline, flange, or custom OEM mounting

- Power Options: 1.5kW to 3.5kW, 120V and 240 V single-phase

- Tube Material: Stainless Steel

Industries & Applications

The SureHeat Hot Air Tool is highly versatile and designed for precision, high-temperature spot heating in constrained or hard-to-access areas, making it ideal for a wide range of industries and applications:

- Automotive & Transportation – Perfect for adhesive activation, panel bonding, heat forming, curing, and component testing, providing consistent heat to maintain production quality and reduce defects in high-volume assembly lines.

- Plastics & Packaging – Ideal for shrink wrapping, sealing, forming, bending, and heat-set applications, delivering controlled localized heat to achieve uniform material performance without damaging surrounding areas.

- Electronics & Semiconductor – Supports quick drying, component sealing, adhesive curing, and reflow soldering, where precise temperature control is critical for sensitive, high-value components.

- Medical & Pharmaceutical – Excellent for packaging, sterilization, laboratory heating, and precision drying, helping facilities meet strict regulatory standards while ensuring safe, uniform results.

- Printing & Converting – Optimized for laminating, coating, shrink wrapping, localized drying, embossing, and other finishing processes, improving product quality and process efficiency.

- General Industrial & OEM – Ideal for hot air knives, small-scale curing, localized heating, and integration into custom machinery, providing reliable performance in OEM applications or challenging production environments.

Compact, durable, and precise, the Hot Air Tool delivers high-temperature, focused airflow exactly where it’s needed, outperforming conventional spot heaters, heat guns, or open-air blowers. Its robust construction and closed-loop temperature control ensure consistent results, energy efficiency, and safety across diverse industrial applications.

Temperature Control

The TUTCO SureHeat Hot Air Tool is designed for precise, reliable temperature management using a dedicated digital temperature controller. This setup ensures accurate, repeatable heating for spot and localized applications.

- Controller Model: F078420 or F076361 – a compact 1/16 DIN-sized temperature controller with NEMA 4X (IP65) front panel for durable industrial use.

- Thermocouple Compatibility: Accepts Type K thermocouple inputs to directly monitor the heater exit temperature.

- Output: 0–20 mA output compatible with TUTCO SureHeat SCR model F066823 and other SCRs for precise power regulation.

- PID Control: Standard PID-type control with a wide proportional band minimizes temperature overshoot. PID parameters may be auto-tuned, but only at temperatures below the maximum rating of the heater. Always monitor the temperature rise and shut power off if it exceeds the heater specification during auto-tuning.

- Power & Connectivity: Input 120/240 VAC, 50/60 Hz. Alarm relay included for process alerts.

- Safety & Compliance: UL Recognized, CSA, and CE certified, ensuring industrial-grade reliability.

Key Benefits

- Maintains consistent, repeatable temperatures for critical processes.

- Reduces risk of overheating or process variability.

- Compact and robust design integrates easily into OEM setups or production lines.

- Versatile compatibility with all TUTCO SureHeat products using thermocouples, adapters, and SCRs.

This temperature controller provides the precision, reliability, and safety required for high-performance localized heating, making the Hot Air Tool a superior choice over conventional hot air guns or open-loop heaters.

Info

Minimizing Hot Air Tools Element Failures

Always ensure air is flowing before powering the heating element. Slowly regulate the ramp up time using the potentiometer to control the AC voltage. Use a temperature controller with 100ms cycle time.

Additional Information

F068472 ........................................ Flare Attachment Accessory

F066823........................................Closed-Loop SCR Power Controller

F076361........................................Digital Temperature Controller

Why Choose TUTCO SureHeat's Hot Air Tools?

Industry Expertise: With decades of experience in industrial heating solutions, TUTCO SureHeat is a trusted name in the industry.

Reliable Performance: Our heaters are designed for consistent, repeatable results, ensuring quality and efficiency in your processes.

Comprehensive Support: We offer technical support, custom solutions, and integration assistance to meet your specific needs.

Global Reach: Our products are used worldwide, providing proven solutions in various industries.

Unlike competitors, the SureHeat Hot Air Tool combines:

- Extreme temperature capability up to 1400 °F (760 °C)

- High-velocity, localized airflow for precise spot heating

- Compact, durable stainless-steel construction for tight or OEM installations

- Closed-loop control integration with thermocouples for repeatable results

- Backed by TUTCO’s decades of industrial heating expertise, Made in the USA

The Hot Air Tool is the preferred solution for manufacturers, OEMs, and industrial facilities that demand precision, reliability, and efficiency in every heating application.

Real-World Results

The TUTCO SureHeat Hot Air Tool, paired with its digital temperature controller, delivers precise, reliable performance in a variety of industrial settings. By combining precision temperature control, high-velocity airflow, and compact industrial design, the Hot Air Tool delivers measurable improvements in speed, quality, energy efficiency, and safety, making it a reliable choice for demanding localized heating applications.

- High Heat in Tight Spaces – Focused, high-velocity airflow delivers powerful, localized heating where conventional spot heaters or heat guns cannot reach.

- Faster Process Cycles – Rapid ramp-up and accurate PID-controlled temperature reduce heating times, improving throughput and overall productivity.

- Consistent Quality – Closed-loop monitoring ensures uniform temperatures, minimizing defects in adhesives, plastics, coatings, or sensitive components.

- Energy Efficiency – Precise temperature regulation prevents wasteful overheating, lowering energy consumption and operational costs.

- Enhanced Safety & Reliability – Over-temperature monitoring and alarm relay reduce the risk of heater or process damage, protecting operators and equipment.

- Versatile Integration – Compatible with OEM systems, production lines, or standalone setups, supporting diverse applications across automotive, electronics, medical, plastics, and printing industries.

- Repeatable Results – PID-controlled feedback ensures each heating cycle matches process requirements, providing predictable performance for high-volume or precision operations.

Frequently Asked Questions

It excels in localized, high-temperature spot heating across industries such as automotive, plastics, electronics, medical, and printing. Typical applications include adhesive activation, component curing, heat forming, shrink wrapping, solder reflow, and small-scale drying or sealing where precision and repeatability are critical.

The heater is engineered for rapid ramp-up, delivering high-temperature air quickly to minimize downtime and improve process efficiency. Operators can rely on near-instant heat for spot applications like adhesive activation, shrink wrapping, or localized curing.

Yes. Its compact, lightweight construction and flexible mounting options (inline, flange, or custom) allow seamless integration into production lines, machinery, or manual setups. The design makes it ideal for processes where conventional blowers or open-air heaters are too large or imprecise.

The Hot Air Tool uses high-velocity, focused airflow combined with a compact, stainless steel design to direct heat exactly where it’s needed. Its closed-loop control with a built-in thermocouple ensures the temperature remains consistent, even in constrained spaces or complex OEM machinery.